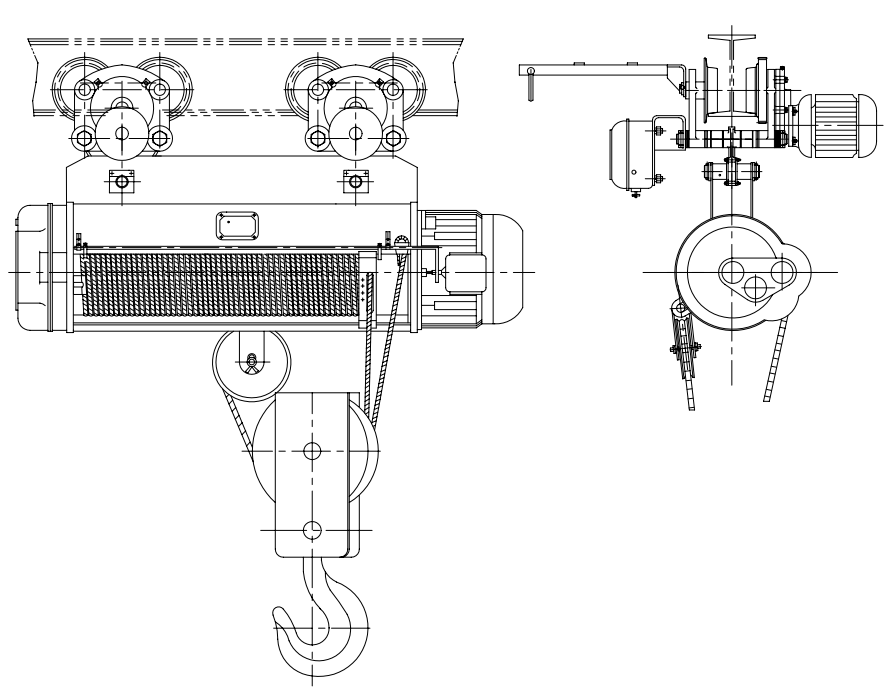

The wire rope electric hoist is a compact, lightweight, small-sized lifting equipment with versatile components and convenient operation. It primarily consists of components such as a motor, transmission mechanism, drum, and wire rope. The motor drives the transmission mechanism, causing the drum to rotate and wind up or release the wire rope, thereby achieving the lifting and moving of heavy objects. It can be used independently or in combination with bridge cranes, gantry cranes, jib cranes, and other lifting devices.

| Model | CD1-0.5 | CD1-1 | CD1-2 | CD1-3 | CD1-5 | CD1-10 |

| Capacity(t) | 0.5 | 1 | 2 | 3 | 5 | 10 |

| lifting height(m) | 6-12 | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 |

| Lifting speed(m/min) | 8 | 8 | 8 | 8 | 8 | 7 |

| Running speed(m/min) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Wire rope type | 6×37-4.8-180 | 6×37-7.4-180 | 6×37-11-155 | 6×37-13-170 | 6×37-15-200 | 6×37-17.5-200 |

| I Beam track type | 16-28b | 16-28b | 20a-32c | 20a-32c | 25a-63c | 28a-63c |

| Motor power(kw) | 0.8 | 1.5 | 3 | 4.5 | 7.5 | 13 |

| Motor R.P.M(r/min) | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 |

| Voltage(V) | 380 or customized | 380 or customized | 380 or customized | 380 or customized | 380 or customized | 380 or customized |

| Frequency(Hz) | 50(60) | 50(60) | 50(60) | 50(60) | 50(60) | 50(60) |

| Phase | 3 | 3 | 3 | 3 | 3 | 3 |

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Crane Industry Park, Xinxiang City, Henan Province