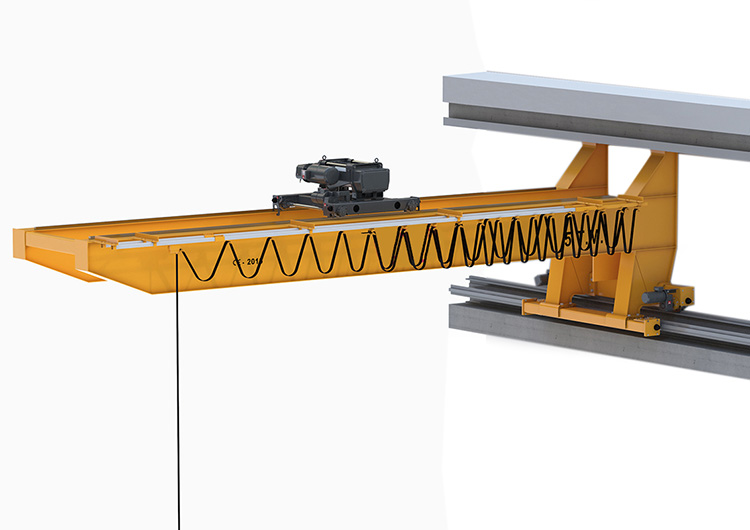

Wall Travelling jib Cranes

Capacity: up to 5 tons

Arm length: up to 10 meters

Lifting height: up to 20 meters

Duty class: A3

Operating voltage: 220V~690V, 50-60Hz, 3-phase AC

Crane control mode: Pendant control/remote control

Description

Wall Travelling jib cranes, widely known as wall jib lift or wall-mounted jib lift, is a lifting equipment fixedly installed on walls or columns. It achieves vertical and horizontal movement of goods through the extension and rotation of the jib, as well as the lifting function of electric or manual hoists. It typically consists of a fixed base, a rotating arm, an electric or manual hoist, and a control system.

Parameters

| Capacity (t) | Lifting height (m) | Lifting speed(m/min) | Crane speed(m/min) | Power supply | Work class |

| 2 | 6-20 | 8 | 8-40 | 3-p 50HZ 380V | A3 |

| 3 | 6-20 | 8 | 8-40 | 3-p 50HZ 380V | A3 |

| 5 | 6-20 | 8 | 8-40 | 3-p 50HZ 380V | A3 |

| 10 | 6-20 | 7 | 2-20 | 3-p 50HZ 380V | A3 |

| 16 | 6-20 | 3.5 | 2-20 | 3-p 50HZ 380V | A3 |

Feature

- High space utilization: Installed on walls or columns, Wall Travelling jib cranes do not occupy ground space, making them suitable for high-rise buildings, workshops, and indoor and outdoor vertical and horizontal transportation applications.

- Strong carrying capacity: The jib is usually made of high-strength steel, possessing sufficient strength and rigidity to bear the weight of heavy loads and various forces during lifting operations.

- Good stability: The column supports the jib, ensuring its stability during lifting operations. At the same time, being fixed to walls or columns, wall jib cranes exhibit excellent stability.

- Convenient operation: Electric or manual hoists can be accurately operated and controlled through the control system, improving work efficiency and safety. The control system also provides precise control of the electric hoist, enabling lifting, lowering, rotating, and other movements, and incorporates safety protection features such as overload protection and limit protection.

- Economical and practical: Wall Travelling jib cranes have a relatively simple structure, low manufacturing costs, and relatively low maintenance costs, offering high cost-effectiveness.

Applications

- Factory production lines: In automated or semi-automated production lines, Wall Travelling jib cranes can quickly handle raw materials, semi-finished products, or finished products, enhancing production efficiency.

- Warehouse management: In large warehouses, jib cranes can effectively utilize vertical space for rapid cargo retrieval, reducing labor costs and time consumption.

- Logistics centers: In fast-paced logistics operations, jib cranes can quickly respond and accurately transfer goods from one location to another, accelerating cargo circulation.

- Maintenance workshops: In environments requiring frequent replacement of parts or tools, such as automobile repair shops or machine shops, jib cranes can conveniently provide needed items, improving work efficiency.

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: [email protected]

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice