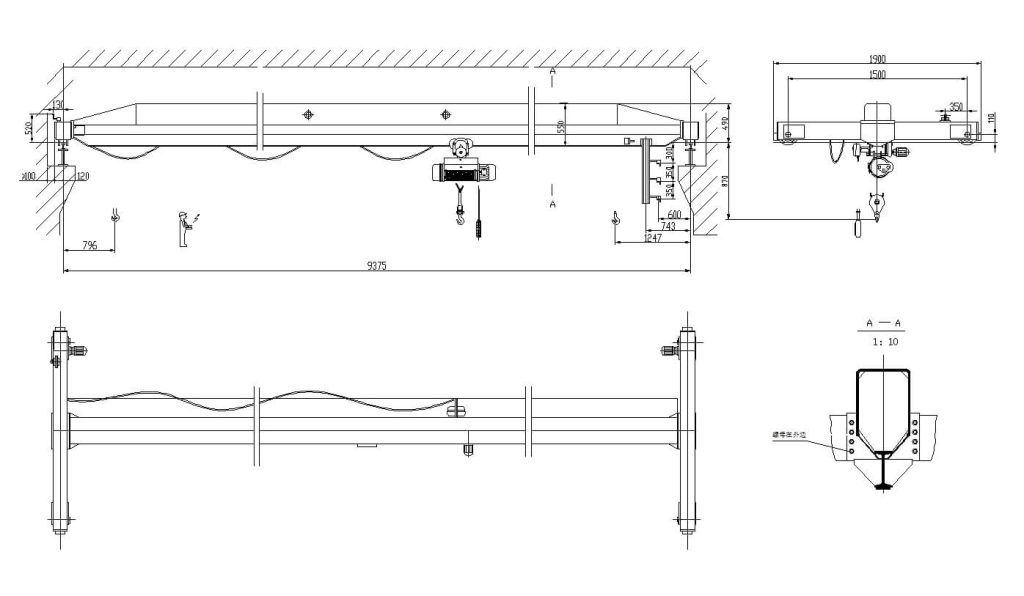

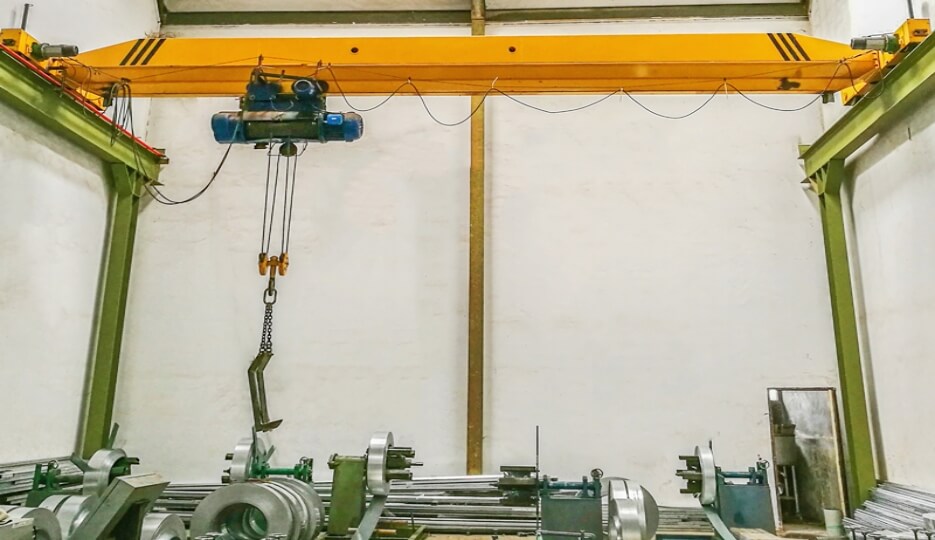

The single girder Overhead crane is a material handling equipment specifically designed for industrial environments such as factories and warehouses, aiming to meet the demands for efficient and accurate material handling in modern production processes. Its distinguishing feature lies in its single-girder structure, which not only results in lighter weight and a more compact appearance but also facilitates installation and maintenance. The main girder and end beams are manufactured from high-strength steel, ensuring the crane's load-bearing capacity and stability. Furthermore, the single-girder bridge crane adopts a modular design, allowing for customization according to specific needs to adapt to various operational environments. This crane is widely used in industries such as manufacturing, logistics, and construction, becoming an indispensable material handling tool in these sectors.

| Capacity(t) | Span(m) | Lifting height(m) | Lifting speed(m/min) | Power Supply Voltage | Work class |

| 1ton | 7.5-28.5 | 6-30 | 8 or 8/0.8 | 220V-660V, 50-60Hz, 3ph AC | A3-A5 |

| 3ton | 7.5-31.5 | 6-30 | 8 or 8/0.8 | 220V-660V, 50-60Hz, 3ph AC | A3-A5 |

| 5ton | 7.5-31.5 | 6-30 | 8 or 8/0.8 | 220V-660V, 50-60Hz, 3ph AC | A3-A5 |

| 10ton | 7.5-31.5 | 6-30 | 7 or 7/0.7 | 220V-660V, 50-60Hz, 3ph AC | A3-A5 |

| 16ton | 7.5-31.5 | 6-30 | 3.5 or 3.5/0.35 | 220V-660V, 50-60Hz, 3ph AC | A3-A5 |

| 20ton | 7.5-31.5 | 6-30 | 3.5 or 3.5/0.35 | 220V-660V, 50-60Hz, 3ph AC | A3-A5 |

| 32ton | 7.5-31.5 | 6-30 | 2.3/0.23 | 220V-660V, 50-60Hz, 3ph AC | A3-A5 |

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Crane Industry Park, Xinxiang City, Henan Province