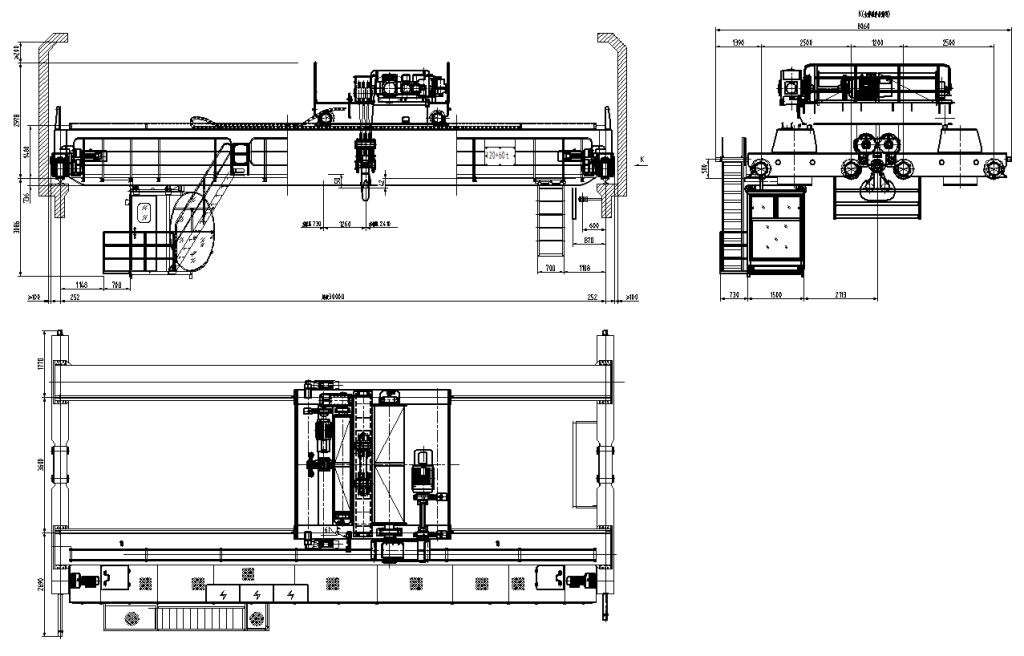

Double Beam Gantry Crane Structure Diagram: Name of Each Part

Meta Description: Explore a detailed breakdown of the double beam gantry crane structure diagram, including key components like the main girder, end carriages, hoist, and more. Learn how each part ensures optimal performance in industrial lifting.

Double Beam Gantry Crane Structure Diagram: Name of Each Part

A double beam gantry crane is a robust lifting solution widely used in industries such as construction, manufacturing, and logistics. Understanding its structure and components is critical for safe operation and maintenance. Below, we break down the key parts of a double beam gantry crane with a clear diagram and descriptions.

Key Components of a Double Beam Gantry Crane

1. Main Girder (Bridge Girder)

2. End Carriages

Located at both ends of the main girder, the end carriages house wheels that allow the crane to move along rails or runways. They ensure smooth lateral movement across the workspace.

3. Hoist and Trolley

- Hoist: The lifting mechanism (electric or manual) that raises/lowers loads.

- Trolley: A movable unit that travels along the main girder, carrying the hoist horizontally.

4. Legs (Support Columns)

Vertical legs support the main girder and transfer loads to the ground. Adjustable legs are available for cranes operating on uneven surfaces.

5. Crab Unit

The crab unit combines the trolley and hoist, enabling precise positioning of heavy loads.

6. Runway Rails

Steel runway rails guide the crane’s movement. They are anchored to the ground or elevated structures for stability.

7. Electrical Panel and Controls

The electrical panel houses wiring and circuits, while control systems (pendant, remote, or cabin-operated) manage crane operations.

8. Safety Features

- Limit switches: Prevent over-travel of the crane or hoist.

- Bumpers: Absorb impact during movement.

- Emergency stop: Halts operations instantly.

Applications of Double Beam Gantry Cranes

These cranes are ideal for:

- Heavy machinery assembly

- Shipping yards for container handling

- Steel fabrication workshops

- Warehouse material handling

Why Choose a Double Beam Design?

- Higher load capacity (up to 500 tons or more).

- Enhanced durability for demanding environments.

- Flexible configurations (fixed, adjustable, or portable).

Why Choose Us?

✅ 42 Years of Crane Manufacturing Expertise

✅ CE/FEM/ISO 9001 Certified Production

✅ 3-Year Structural Warranty + Lifetime Support

✅ 97.3% On-Time Delivery Rate Across 18 Countries

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: [email protected]

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice