Understanding the Structure of an Overhead Bridge Crane: Key Components Explained

Meta Description: Discover the main components of a overhead bridge crane structure, including girders, end carriages, hoists, and safety systems. Learn how each part ensures efficient lifting operations.

Structure of an Overhead Bridge Crane: Core Components and Their Roles

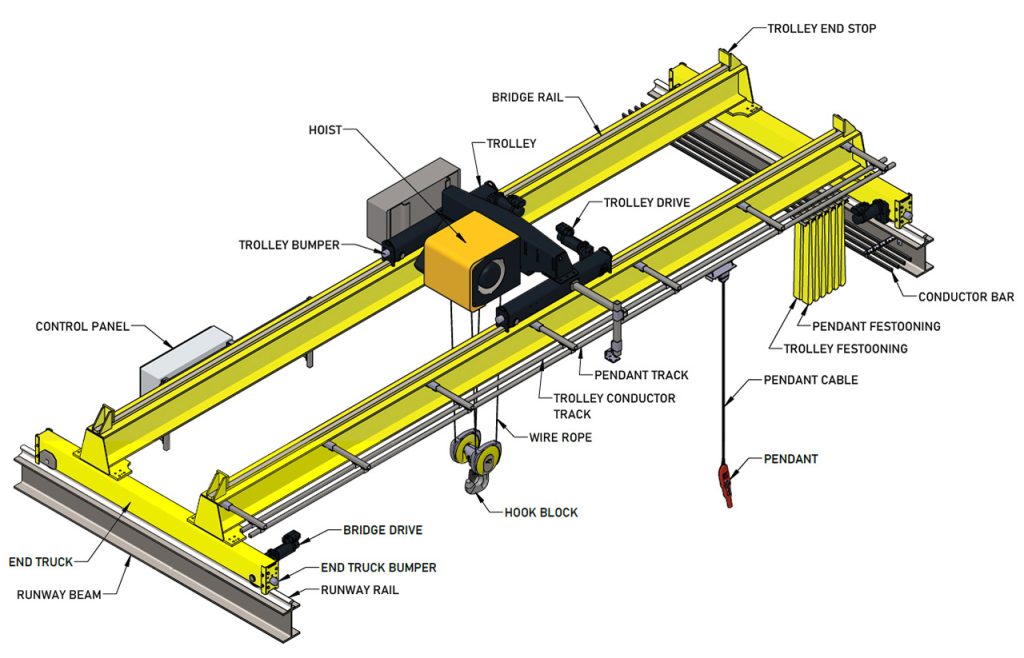

Overhead bridge cranes are essential for heavy lifting in industries like manufacturing, warehousing, and construction. Understanding their structure is critical for optimizing performance and safety. Below, we break down the key components of a bridge crane:

1. Bridge Girder (Main Beam)

The primary horizontal beam spans the workspace and supports the crane’s load. Made from high-strength steel, it’s designed to resist bending and torsional forces. Double-girder cranes handle heavier loads, while single-girder models suit lighter applications.

2. End Carriages

Located at both ends of the bridge girder, these vertical frames house wheels that enable lateral movement along runway rails. Precision bearings ensure smooth travel across the workspace.

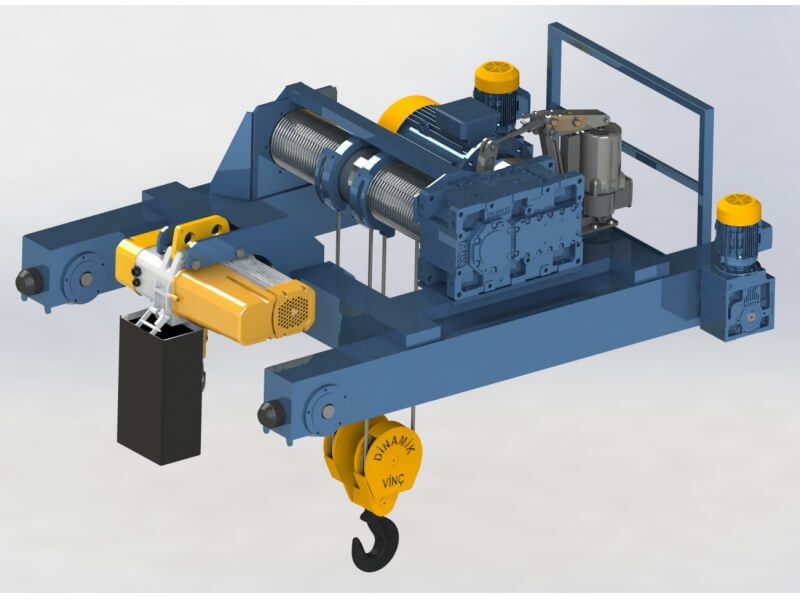

3. Hoist and Trolley

Hoist: The lifting mechanism (electric or manual) includes a motor, drum, wire rope, and hook. It handles vertical load movement.

Trolley: Mounted on the girder, it moves the hoist horizontally to position loads accurately.

4. Runway System

Comprises elevated rails installed on building columns or supports. The crane travels along these rails to cover the entire work area.

5. Electrical and Control Systems

Power Supply: Collectors or festoon systems deliver electricity to the crane.

Controls: Pendant stations or wireless remotes allow operators to manage lifting, lowering, and traversing.

6. Safety Features

Limit Switches: Prevent overtravel of the hoist or bridge.

Overload Protection: Sensors block operations if loads exceed capacity.

Brakes: Ensure immediate stopping in emergencies.

7. Additional Accessories

Cabinets: Protect electrical components from dust and moisture.

Lighting and Alarms: Enhance visibility and warn workers during operations.

Why Choose a Modular Bridge Crane Design?

Modern bridge cranes use modular components for easy customization, maintenance, and scalability. High-grade materials like ISO-certified steel and corrosion-resistant coatings extend equipment lifespan.

Conclusion

A well-designed bridge crane combines robust structural elements with advanced safety and control systems. By understanding its components, businesses can select the right crane for their operational needs while ensuring compliance with OSHA and ISO standards.

All News

Recent Posts

2025/1/25

2025/2/7

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: [email protected]

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice