Bridge Crane Structural Features

When it comes to heavy lifting in industrial environments, bridge cranes (overhead cranes) are indispensable for their strength, precision, and versatility. Understanding their structural design is key to maximizing their efficiency and safety. This article delves into the core structural features of bridge cranes, explaining how their components work together to handle demanding tasks in factories, warehouses, and shipyards.

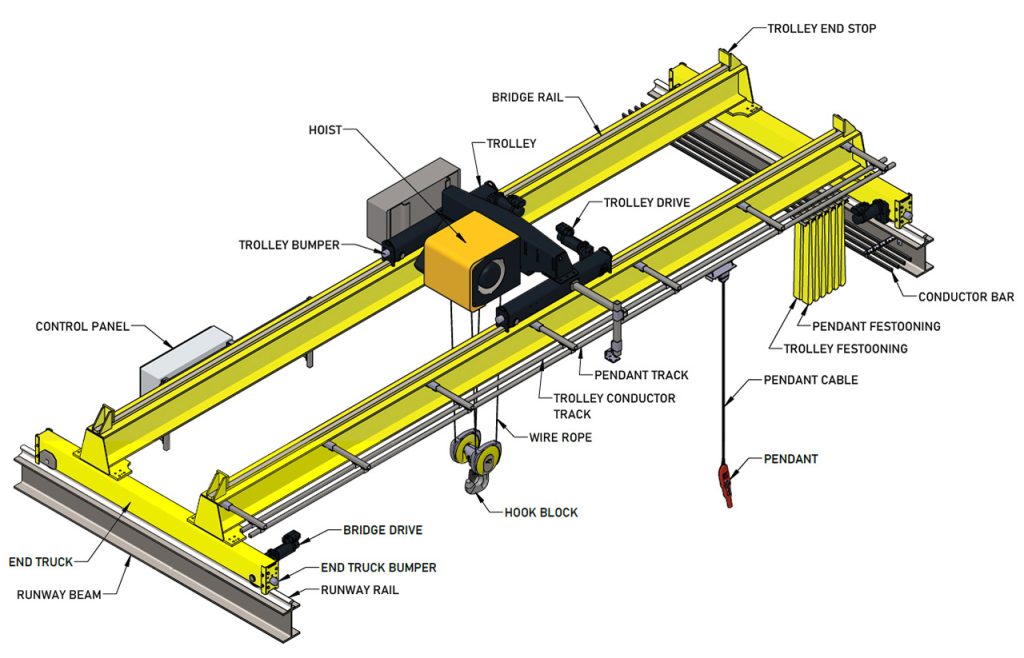

1. Girder Systems: The Backbone of a Bridge Crane

The main girders and end girders (end trucks) form the crane’s primary framework:

-

Double Girder Design:

- Most industrial bridge cranes feature two parallel girders spanning the workspace. These girders distribute the load evenly and provide superior stability, making them ideal for heavy-duty applications (e.g., lifting 20–550+ tons).

- Common materials: Welded steel boxes or reinforced I-beams for high rigidity and resistance to bending.

-

Single Girder Design:

- A lighter alternative with one main girder, often used for lighter loads (≤20 tons) in workshops or warehouses.

- Compact and cost-effective but less suitable for extreme loads or long spans.

2. End Trucks and Runway Beams

-

End Trucks:

- Located at both ends of the main girders, these components house the wheels and motors that move the crane along the runway beams.

- Design: Typically made from heavy-duty steel with adjustable wheelbases to accommodate alignment variations.

-

Runway Beams:

- Installed along the length of the facility, these beams support the entire crane system.

- Materials: Steel or reinforced concrete structures designed to handle dynamic loads and vibrations.

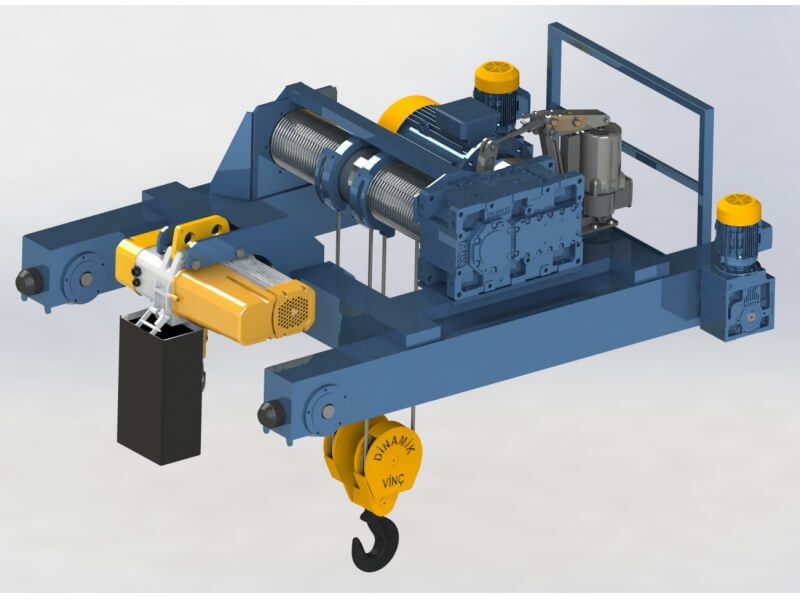

3. Hoist and Trolley Mechanism

The hoist (lifting device) and trolley (movement system) are critical for vertical and horizontal load handling:

-

Hoist Types:

- Electric chain hoists: Lightweight and suitable for precise, low-capacity tasks.

- Wire rope hoists: Heavy-duty lifting with higher speeds and capacities.

-

Trolley Design:

- The trolley moves the hoist horizontally along the girders.

- Components: Motors, gears, brakes, and wheels ensure smooth travel and precise positioning.

4. Drive Systems: Powering Movement

Bridge cranes use two primary drive configurations:

-

Top-Running Cranes:

- Wheels run on rails mounted on the top of runway beams.

- Advantages: Higher load capacities, ideal for heavy industries like steel mills.

-

Under-Running Cranes:

- Wheels attach to the bottom flange of suspended runway beams.

- Advantages: Space-saving design for facilities with limited headroom.

5. Control and Safety Features

Modern bridge cranes integrate advanced technologies for safe and efficient operation:

-

Variable Frequency Drives (VFDs):

- Enable smooth acceleration/deceleration, reducing load swing and mechanical stress.

-

Safety Systems:

- Overload protection: Sensors halt operation if weight exceeds safe limits.

- Limit switches: Prevent trolley and bridge movement beyond set boundaries.

- Anti-collision systems: Essential for multi-crane facilities.

6. Customizable Structural Enhancements

Depending on the application, bridge cranes can be upgraded with:

- Specialized Coatings: Anti-corrosion treatments for harsh environments (e.g., chemical plants).

- Explosion-Proof Components: Certified for use in flammable or hazardous areas.

- Automation: Integration with PLCs or IoT systems for unmanned operations.

7. Key Applications by Industry

- Manufacturing: Moving raw materials, machinery, and finished products.

- Power Generation: Handling turbines, generators, and transformers.

- Shipping: Loading/unloading cargo containers or ship components.

8. Advantages of Bridge Crane Structures

- High Load Capacity: Double girders and robust materials support extreme weights.

- Precision: Smooth trolley and bridge movement enable millimeter-level positioning.

- Durability: Designed for 10–30+ years of service with minimal maintenance.

- Scalability: Modular designs allow upgrades (e.g., adding a second hoist).

Conclusion

The structural design of a bridge crane directly impacts its performance, safety, and lifespan. From the double girder framework to advanced control systems, every component plays a role in ensuring reliable heavy lifting. Whether your facility handles lightweight assembly lines or massive industrial loads, understanding these structural features helps you choose a crane that aligns with your operational needs.

All News

Recent Posts

2025/1/25

2025/2/7

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: [email protected]

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice