Electric Single Girder Cranes vs. Bridge Cranes: Key Differences and Applications

In industrial and construction settings, selecting the right crane is critical for optimizing efficiency, safety, and cost-effectiveness. Two common types of lifting equipment—electric single girder cranes and bridge cranes (double girder overhead cranes)—serve distinct roles depending on load requirements, workspace constraints, and operational demands. This article breaks down their structural differences, capabilities, and ideal use cases to help businesses make informed decisions.

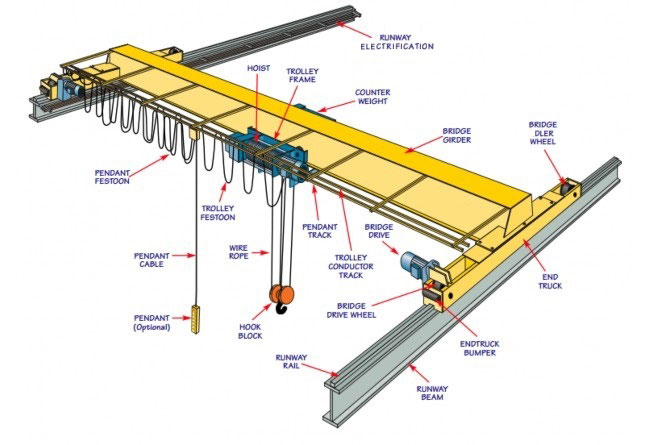

1. Structural Design and Components

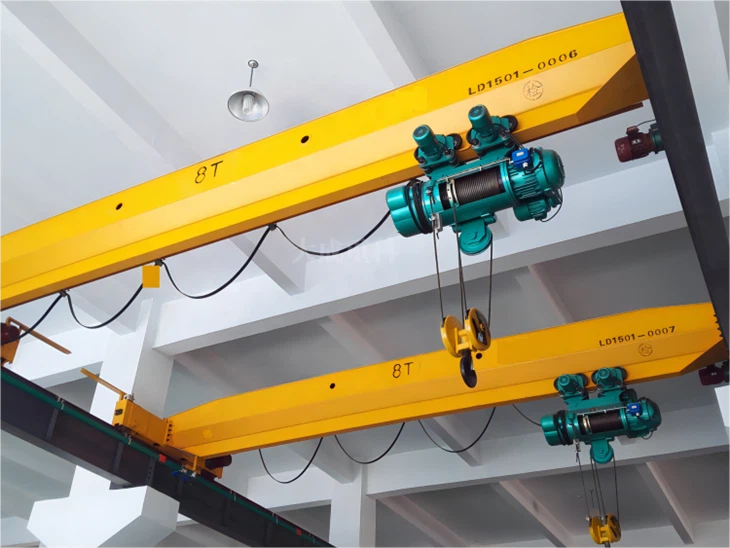

Electric Single Girder Crane

- Single Main Girder: Features one horizontal beam (girder) supporting the hoist and trolley.

- Compact Build: Lightweight design with a lower profile, ideal for facilities with height restrictions.

- Hoist Placement: The hoist travels along the bottom flange of the girder, maximizing vertical lifting space.

Bridge Crane (Double Girder Overhead Crane)

- Double Main Girders: Two parallel girders provide enhanced stability and load distribution.

- Robust Construction: Heavier and taller structure to accommodate larger loads and higher lifting heights.

- Hoist Placement: The hoist operates between the two girders, requiring more vertical clearance but enabling greater hook height.

2. Load Capacity and Span

| Feature | Single Girder Crane | Double Girder Bridge Crane |

|---|---|---|

| Max Load Capacity | Up to 20 tons | 20–550+ tons |

| Span Range | 5–25 meters | 10–35+ meters |

| Lifting Height | Moderate | High |

Why It Matters:

- Single girder cranes are suitable for light to medium loads (e.g., workshops, warehouses).

- Double girder bridge cranes handle heavy-duty applications (e.g., steel mills, shipyards).

3. Operational Efficiency

Single Girder Crane

- Speed: Lower lifting and travel speeds due to lighter-duty motors.

- Precision: Ideal for repetitive, low-intensity tasks.

- Energy Use: Consumes less power, reducing operational costs.

Double Girder Bridge Crane

- Speed: Faster hoisting and trolley movement for high-throughput environments.

- Durability: Built for continuous, heavy-duty operation with minimal downtime.

- Customization: Supports advanced features like auxiliary hoists, remote control, or automated systems.

4. Space and Installation Requirements

- Single Girder Crane:

- Requires less headroom and floor space.

- Easier to install in existing facilities.

- Double Girder Bridge Crane:

- Needs significant vertical clearance and a robust support structure (e.g., reinforced columns).

- Installation is more complex and time-consuming.

5. Cost Comparison

- Initial Investment:

- Single girder cranes are 20–40% cheaper due to simpler design and fewer materials.

- Double girder cranes have higher upfront costs but offer long-term ROI for heavy industries.

- Maintenance:

- Single girder cranes have lower maintenance needs but may require more frequent part replacements in intensive use.

- Double girder cranes are built for longevity, with components designed to withstand wear and tear.

6. Industry Applications

Single Girder Cranes Excel In:

- Warehousing: Loading/unlightweight goods.

- Automotive Workshops: Moving engines or components.

- Small Manufacturing: Assembly lines with moderate loads.

Double Girder Bridge Cranes Excel In:

- Heavy Manufacturing: Lifting steel coils, machinery, or large molds.

- Power Plants: Handling turbines or transformers.

- Ports and Shipyards: Moving shipping containers or ship parts.

7. Safety and Compliance

Both crane types must comply with standards like ISO 4301 (crane classifications) and CMAA (U.S.) or FEM (EU) guidelines. Key considerations:

- Single girder cranes: Prioritize load limit switches and anti-collision systems for confined spaces.

- Double girder cranes: Require reinforced brakes, overload protection, and structural stress monitoring.

8. How to Choose Between Them

Ask these questions:

- What is your maximum load requirement?

- How much vertical and horizontal space is available?

- Will the crane operate continuously or intermittently?

- What is your budget for procurement and maintenance?

Conclusion

Electric single girder cranes and double girder bridge cranes cater to different operational scales and industries. While single girder models offer affordability and space efficiency for light-duty tasks, double girder bridge cranes deliver unmatched power and durability for heavy lifting. By evaluating your load demands, workspace, and long-term goals, you can select the crane that maximizes productivity and safety.

All News

Recent Posts

2025/1/25

2025/2/7

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: [email protected]

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice