Overhead Cranes: Applications and Operational Guide

Overhead cranes (also called bridge cranes) have revolutionized material handling across industries through their unique combination of precision, strength, and spatial efficiency. These robust lifting systems enable safe transportation of heavy loads while maximizing floor space utilization. Let’s explore their key applications and essential operational guidelines.

Key Application Areas

1. Manufacturing Facilities

Caption: Overhead cranes positioning vehicle components in an automotive production line.

- Move heavy machinery parts between workstations

- Handle dies in metal stamping operations

- Position large molds in plastic injection processes

- Facilitate assembly of industrial equipment

2. Warehousing & Logistics

Caption: Double girder crane organizing bulk materials in a distribution center.

- Stack heavy pallets in high-bay storage

- Load/unload shipping containers

- Transport oversized inventory items

- Support just-in-time inventory systems

3. Steel & Metal Processing

- Handle molten metal crucibles

- Position heavy ingots and coils

- Service rolling mill operations

- Maintain continuous production flow

4. Automotive Industry

- Install vehicle chassis components

- Position engine blocks during assembly

- Handle stamping press tooling

- Support robotic welding cells

5. Aerospace Sector

Caption: Precision handling of aircraft components using specialized lifting attachments.

- Move wing sections and fuselage panels

- Position jet engine assemblies

- Handle composite material sheets

- Support maintenance hangar operations

6. Energy & Construction

- Install wind turbine components

- Position power plant equipment

- Handle precast concrete elements

- Service hydroelectric dam maintenance

Operational Guidelines

Pre-Operation Checklist:

- 1.Inspect hooks, wires, and brakes

- 2.Verify load capacity matches task

- 3.Clear travel path of obstacles

- 4.Confirm proper lighting conditions

- 5.Test emergency stop functions

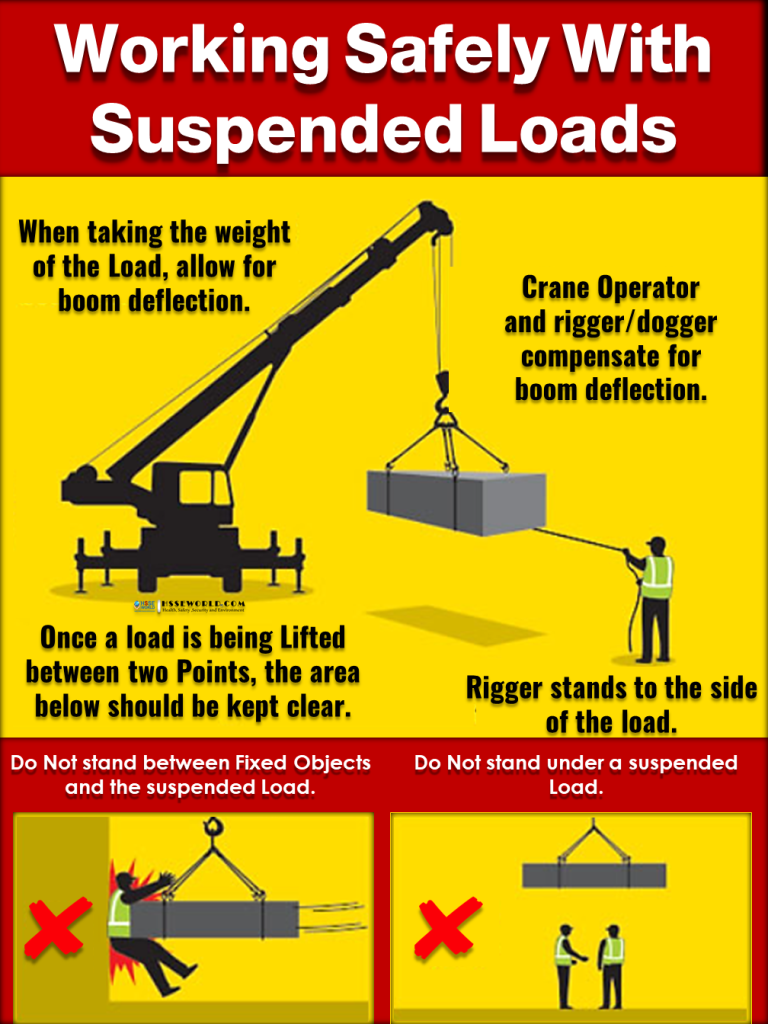

Safe Handling Practices:

- Always center loads below the hook

- Maintain clear communication with spotters

- Avoid sudden acceleration/deceleration

- Never bypass safety limit switches

- Use taglines for precise load positioning

Maintenance Requirements:

- Lubricate moving parts weekly

- Inspect runway beams monthly

- Test overload protection quarterly

- Conduct professional annual certification

Choosing the Right Configuration

| Crane Type | Ideal For | Capacity Range |

|---|---|---|

| Single Girder | Light-duty workshops | 1-20 tons |

| Double Girder | Heavy industrial use | 5-500+ tons |

| Gantry Crane | Outdoor applications | 10-100 tons |

| Monorail | Linear production lines | 1-10 tons |

Conclusion

From automotive plants to spaceport installations, overhead cranes remain indispensable for modern heavy lifting. By understanding their diverse applications and adhering to operational best practices, businesses can significantly enhance workplace safety and productivity.

Contact our engineering team today to design a customized overhead crane solution for your specific needs.

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: [email protected]

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice